Mojo Dialer is the supreme prospecting system that enables individuals to make at least 300 telephone calls per hr. It goes along with scores of features such as the Mojo...

View ProfileBest Manufacturing Execution Software

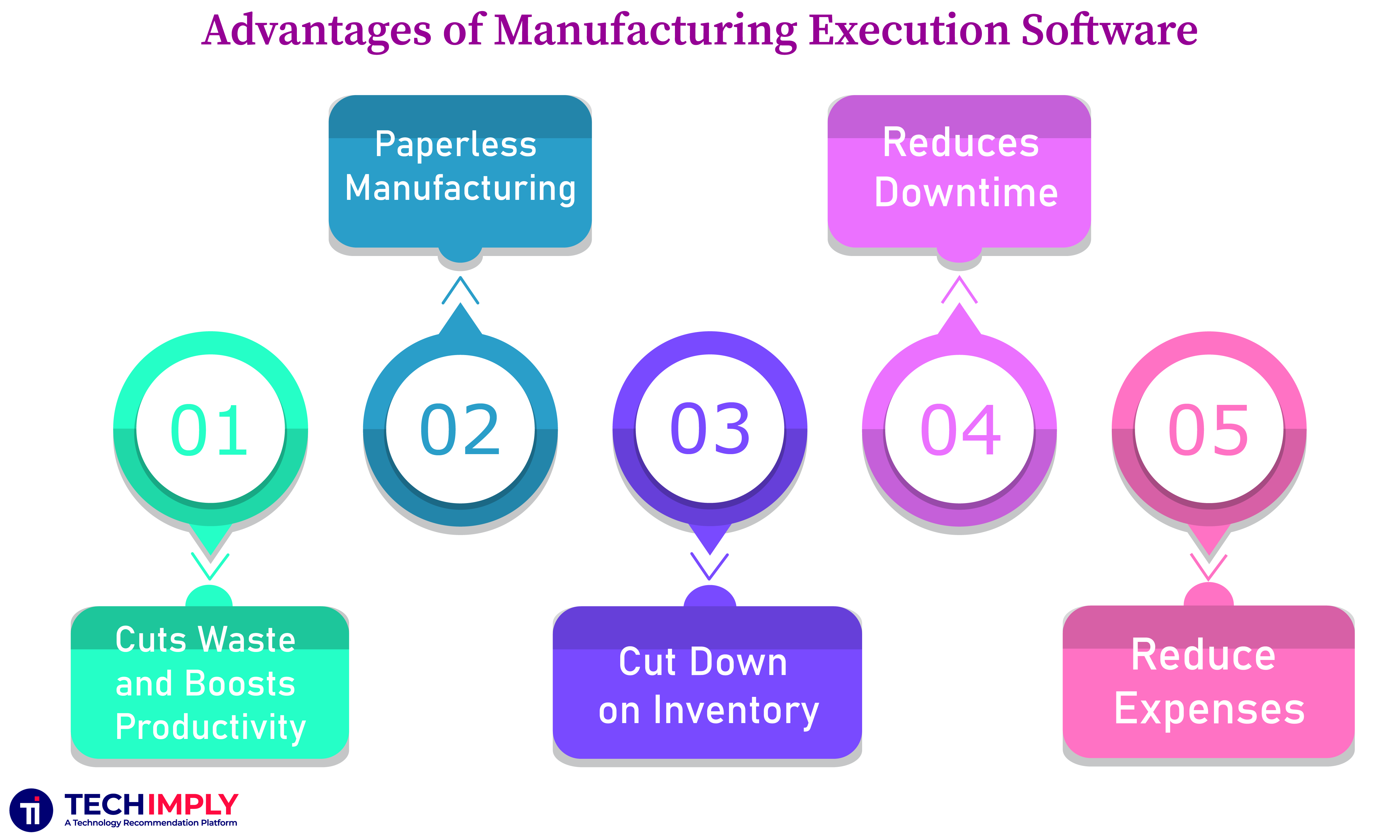

Check out the Best Manufacturing Execution Software Listing on Techimply. We have a list of the best Manufacturing Execution Software Selecting or switching to the perfect Manufacturing Execution Software for your company involves deep business thoughtful research and analysis of the features and system capabilities that will best suit your business now and scale with you as you grow. Although there are many Manufacturing Execution Software options selecting the one that aligns with your requirements becomes crucial. This guide will provide you with an in-depth understanding of Manufacturing Execution Software and assist you in selecting the best one for your business.

List of Top Manufacturing Execution Software in India | Get Free Demo

Every enterprise has a project. What's ours? To empower all and sundry and each enterprise to obtain greater. We consider era can and have to be a pressure for correct...

View ProfileCheck How JitBase can help to automate Indian Business. Techimply provide their list of features, pricing, Free demo and Comparison with the best alternative

View ProfileCheck How cmExe can help to automate Indian Business. Techimply provide their list of features, pricing, Free demo and Comparison with the best alternative

View ProfileCheck How ZOOMFAB can help to automate Indian Business. Techimply provide their list of features, pricing, Free demo and Comparison with the best alternative

View ProfileCheck How Sequor MES can help to automate Indian Business. Techimply provide their list of features, pricing, Free demo and Comparison with the best alternative

View ProfileCheck How Match-IT can help to automate Indian Business. Techimply provide their list of features, pricing, Free demo and Comparison with the best alternative

View ProfileCheck How Smactory can help to automate Indian Business. Techimply provide their list of features, pricing, Free demo and Comparison with the best alternative

View ProfileCheck How PerfTrak can help to automate Indian Business. Techimply provide their list of features, pricing, Free demo and Comparison with the best alternative

View ProfileCheck How MYOB Advanced Manufacturing can help to automate Indian Business. Techimply provide their list of features, pricing, Free demo and Comparison with the best alternative

View ProfileIFS develops and delivers enterprise software for companies around the world that manufacture and distribute goods, build and maintain assets, and manage service-focused operations. Within our single platform, our industry-specific...

View ProfileCheck How Mes Framework can help to automate Indian Business. Techimply provide their list of features, pricing, Free demo and Comparison with the best alternative

View ProfileCheck How MIM.365 can help to automate Indian Business. Techimply provide their list of features, pricing, Free demo and Comparison with the best alternative

View ProfileCheck How PILOT:Suite can help to automate Indian Business. Techimply provide their list of features, pricing, Free demo and Comparison with the best alternative

View ProfileCheck How PlanetTogether can help to automate Indian Business. Techimply provide their list of features, pricing, Free demo and Comparison with the best alternative

View ProfileCheck How Tempo Manufacturing Execution System can help to automate Indian Business. Techimply provide their list of features, pricing, Free demo and Comparison with the best alternative

View ProfileCheck How Cosmino MES Plus can help to automate Indian Business. Techimply provide their list of features, pricing, Free demo and Comparison with the best alternative

View ProfileCheck How LYNQ MES can help to automate Indian Business. Techimply provide their list of features, pricing, Free demo and Comparison with the best alternative

View ProfileCheck How TRIM SUITE can help to automate Indian Business. Techimply provide their list of features, pricing, Free demo and Comparison with the best alternative

View ProfileCheck How PRIMAC can help to automate Indian Business. Techimply provide their list of features, pricing, Free demo and Comparison with the best alternative

View Profile

Frequently Asked Questions (FAQs)

MES is a software solution that bridges the gap between planning and production by managing and monitoring manufacturing operations on the shop floor. It provides real-time visibility into production processes, helping optimize efficiency, quality, and overall performance.

MES typically includes functionalities such as production scheduling, work order management, quality management, inventory tracking, real-time monitoring, performance analysis, and reporting. These features collectively enhance the control and execution of manufacturing operations.

MES improves production efficiency by optimizing scheduling, reducing downtime, automating manual processes, and providing real-time data on machine and labor performance. It helps minimize bottlenecks and enhances overall workflow.

Yes, MES is designed to integrate with other enterprise systems like Enterprise Resource Planning (ERP), Supply Chain Management (SCM), and Customer Relationship Management (CRM) systems. Integration ensures seamless data flow and consistency across different business functions.

MES is adaptable and can be customized for various manufacturing industries, including discrete manufacturing, process manufacturing, and mixed-mode manufacturing. It caters to industries such as automotive, aerospace, electronics, pharmaceuticals, and more.

0.0

0.0